HS-AA

Vapor Phase, Activated Alumina

Hydrosil’s HS-AA is designed for air and gas drying. The activated alumina uses a process called adsorption to dry air and gas. Activated alumina is manufactured from aluminium hydroxide which is dehydroxylated creating a porous material. The porous material works as a desiccant which when immersed in a liquid the material will not soften or deteriorate. When heated to approximately 350°F-600°F, HS-AA will release the water molecules that were adsorbed and the material can be reused. Common industries that use activated alumina are:

- Air Dryers

- Drinking Water

- Refineries

- Catalyst Applications

Activated alumina is often altered to increase affinity to select pollutants such as arsenic (HS-AS) and fluoride (HS-F).

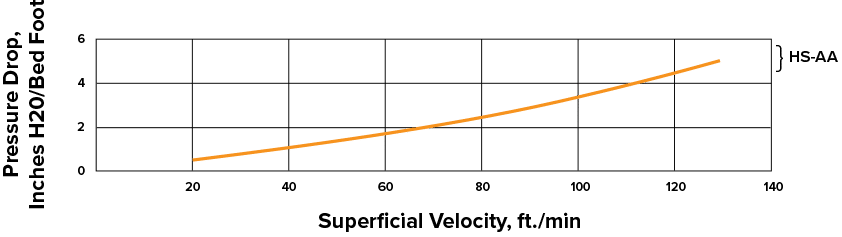

HS-AA Pressure Drop

typical physical properties

| Property: | Value: |

| Apparent Density, lb/ft 3 | 43-45 |

| U.S. Standard Sieve Size (Mesh Size) | 3 x 5, 14 x 28 |

| Specific Surface Area, m2/g | 300 |

| Crush Strength, lb | 20 |